Propeller Trouble Shooter

When was the last time you really checked your propeller thoroughly?, have you noticed a drop off in speed?, does your boat vibrate more than it used to?, does it use more fuel?, chances are that most boat owners will have experienced one or more of these symptoms at some time, if so the following tips could save you money and make your boating a more pleasurable experience.

So what are the recommendations? The first step is to have a look at the prop, if there are any obvious signs of damage i.e. big dents, severe bends, missing pieces or even missing blades etc!!, don’t laugh it happens the propeller defiantly needs repairing. If you feel the prop looks fairly OK run you fingers around the propeller blades taking particular attention to the leading edge. The blade should be smooth if you can feel any damage in the form of burrs, pieces missing or bends however minimal it will signify that the propeller has at some stage come into contact with a submerged object, don’t forget anything you can feel counts as damage, it seems that many people think that a small amount of damage is acceptable- this is not so and here’s why---Damage to the blades will affect the performance in two basic ways. (1.) If you think of the propeller purely as a wheel for a moment any damage will affect it’s dynamic balance, much like a car with out of balance wheels, as an example of how critical this is just look at how small the balance weights are on your car in relation to the size of the wheels. (2.) Possibly the most significant affect of damage will be on the hydrodynamic qualities of the propeller, people forget that the blades are in effect small wings spinning at very high speed in fact anything up to three or four thousand RPM, at these speeds the water flowing over them is traveling extremely fast and therefore even slight damage will have a very significant effect on the water flow and reduce the overall efficiency. If you do find any damage then it’s time to remove it and have it repaired, we wouldn’t recommend a DIY repair as they are rarely successful and usually end up in the prop being beyond repair, you wouldn’t believe the damage a grinder can cause in the hands of the inexperienced !!. It is very cost effective to have your propeller professionally repaired and serviced the average cost of a repair is about £38.50 + VAT and you will almost certainly save this outlay with increased efficiency and fuel economy.

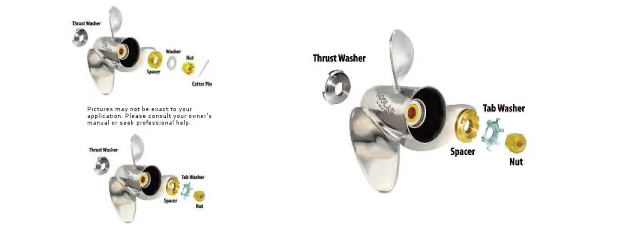

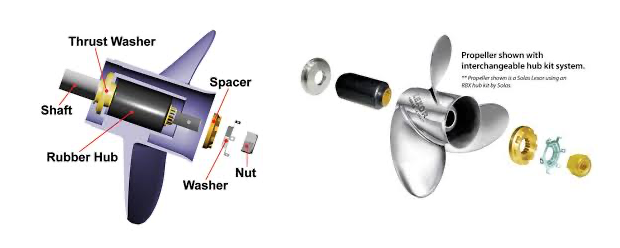

If you have noticed any damage on your inspection the next step would be to remove the propeller from the shaft. Most outboards or sterndrives will either have a split pin or tab washer arrangement and you can use general tools or purchase a propeller wrench to remove the prop. For split pin types, remove the pin by pinching it together with a pair of pliers and pull thru the hole in the shaft next undo the nut some engines will have a nut end spacer this needs to be removed the propeller should then slide off the splined shaft. For tab washer fitting, bend the tab down to allow the nut to turn if you are using a screwdriver to get the tab washer off make sure you do not lever onto the exhaust ring as it can easily split or become damaged, next undo the nut and remove the tab washer and any nut end spacer the propeller should then slide off the shaft. For either type, don’t forget that there is a thrust washer behind the propeller. It is very important when removing the propeller to ensure that you locate the thrust washer, it often gets stuck onto the back of the propeller and goes un-noticed and therefore doesn’t get refitted. Without the thrust washer the propeller will move forward into the engine gearcase causing damage to both. Removing the propeller is a simple operation, just take your time and make a careful note of how the washers etc fit so you know how it all goes back together.

To arrange a propeller repair either take or send the prop to a specialist repair company, OK this may sound obvious but it is surprising the amount of props we see that have been “repaired by a mate” that subsequently have problems. Most repair companies will have a set fee for propeller blade repairs so you will know before the job is done how much it will cost. Prop repair prices will usually be determined by diameter and material i.e. aluminum stainless steel or bronze. The size will normally be marked on the propeller and is given as diameter x pitch. The diameter is determined by doubling the distance between the blade tip and the centre of the hub. Diameter can also be looked at as the distance across a circle that the propeller would make when rotating. Once in the hands of the workshop the following process will be carried out. Most workshops will be dealing with many propellers so upon arrival each propeller will usually be serial numbered, this is to ensure that the correct propeller is returned to the rightful owner. The First step will be a visual inspection of the damage to the blades, if the propeller has a rubber bush this is dry torque tested and the exhaust ring checked. Next the blades are straightened by using the appropriate pitching block depending on the propeller make, size and pitch. If the propeller has any pieces missing or the edges are rough then it will be welded to bring the propeller up to the correct profile. Special care will be taken to ensure there is no heat transference to the rubber bush or any plastic/composite parts. After welding the propeller needs to be ground and finished, the propeller is shaped into profile keeping continuity between each blade. The minimal amount of material will be removed to ensure strength and to prolong the life of the propeller. The propeller will be checked for pitch and any adjustments will be made. The prop is then dynamically balanced to give smooth power and economy from your engine and to ensue that it runs vibration free. Next the prop will be finished, aluminum propellers are painted, stainless steel and bronze ones will be satin finished. The last step will be to carry out a quality control check to ensure the propeller is as good as new before it is released for collection or delivery. The process will usually be carried out in about 3-4 days. Once you get the propeller back refit by applying some grease to the shaft, fit the thrust washer, propeller, then relevant spacers, tab and nut or nut split pin etc. Gently rotate the propeller to ensure that there is no binding or fouling and make sure the tab is bent around the nut or the pin is securely fitted. Most propellers are repairable as long as there is at least 2/3rds of each blade left. If you want to increase or decease the rpm of your engine you can you also have the pitch of your propeller altered at the time of repair at no extra cost by one inch up or down. As well as repairing props most propeller repair workshops will also offer a specialized blue printing service, repairs to skegs from lower units, rebushing and replacement exhaust rings.

If no signs of damage were noted, I would still commend that you remove the propeller. If there is any growth on the propeller you can remove it with a bit of elbow grease and a scouring pad, try the ones suitable for nonstick pans as these should not scratch the surface. Don’t forget that barnacles and weed will affect the flow of the water over the propeller blades so if there is any it is worthwhile removing it. If the prop is aluminum check the paint finish and if necessary apply a new coat. If applying paint make sure it is suitable for paining onto aluminum, most aerosol paints sold for car repair touch ups will be suitable and follow the paint manufactures instructions. If the propeller is stainless steel, it may have a calcium build up on the blades, you can remove this by using a scouring pad or a descaler. If you do use a descaler ensure that this does not come into contact with any of the rubber or plastic parts of the propeller. Once cleaned refit the propeller. If there is absolutely nothing wrong with the propeller you should remove it from the shaft once a year, grease the shaft and refit this will ensure that the propeller does not become seized onto the shaft.

If you have a performance boat and are looking for the optimum you may consider having your propeller blue printed / lab finished. Both lab finishing and blueprinting refer to the process used to insure the accuracy of the propeller rake angle, pitch, progression, pitch variation and cup. Most propellers will have manufacturing variances to some degree so if you remove these inaccuracies it will help to improve performance. Blue printing is a hand process which involves thinning the blades and sharpening the leading edges. The advantage of blueprinting is that it reduces the horsepower required to turn the propeller and generates more usable horsepower for thrust. The disadvantages of this same thinning and sharpening are reduced blade strength, fatigue resistance, and being more subjective to stress risers occurring at the sharpened leading edge. A sharp leading edge is very prone to minute nicks which create stress risers. These stress risers often propagate cracks that originate from the nick at the leading edge and work their way through the blade. The same thing is true for any nicks at the trailing edge. Consequently, there is no warranty for any propeller that has been lab finished or blueprinted and this must be considered when weighing the advantages and disadvantages so you can make an informed decision

Thru the season keep a check on how the propeller is working. If you notice any vibrations check the propeller for signs of impact damage and repair if necessary. If you notice that you are experiencing “slip” on acceleration or in tight turns this will probably be caused by cavitation. Cavitation is quite common and often mis diagnosed as bush failure as the symptoms are similar. If the propeller has any signs of damage it will cavitate especially when accelerating or turning. Even very minimal damage or fouling can cause the propeller to cavitate. The flow of water over the propeller blades needs be smooth, if or example there is a small chip on the leading edge this will cause air bubbles to be formed the process of cavitation will begin and the performance of your boat will suffer. The loss of a converging or exhaust ring from a thru-hub exhaust propeller will mean that the exhaust gases going through the propeller could either escape between the propeller and the gear casing if the converging ring is missing or not being properly deflected if the exhaust ring is missing. The converging ring is located at the engine end of the propeller and the exhaust ring is at the nut end of the propeller. Most outboard and sterndrive propellers will have a rubber bush or bush kit. A propeller bush acts like a shock absorber and decreases the stresses to which the lower unit and engine gears are subjected to in the cases of sudden engagement of drive or when the propeller hits an obstruction. Propeller bushes are usually reliable. If your bush is damaged you will get little drive from it probably only walking pace. If you do have a faulty propeller bush this can usually be replaced. So if you experience slip make a note of when it happens is the boat going faster than walking pace, if so its probably cavitation or ventilation if you can only limp along it may be bush failure, the difference in cost to repair blades only as opposed to rebushing or replacing the propeller can be significant.

In conclusion;

(1) ALWAYS carry a spare propeller for use in emergencies, a spare propeller may mean the difference between getting your boat home or not. Carrying a spare propeller will mean that you can always use your boat, if you damage a prop you will have another to use. Also if you do damage a propeller you will have one to use whilst your other is being repaired. Propellers can be purchased at reasonable costs and it is more cost effective in the long run to carry a spare so you can use your boat whenever you wish. There is nothing worse than looking forward to using your boat and you can't because you have a damaged prop.

(2) To avoid problems removing your propeller make sure you grease the propeller shaft with a water proof grease such as Quicksilver’s 2-4C before you fit the prop.

(3) NEVER run a vessel for long periods with a damaged propeller as you may cause some sever damage to your engine and stern gear.

(4) To avoid problems of corrosion, propellers and stern gear must NEVER be coated with standard anti-fouling or metal based paints. If you use an anti-fouling intended for use on stern gear and propellers you must ensure that you follow the manufacturer’s instructions to the letter which usually states that bare metal, particularly aluminum, must be primed prior to application.

(5) Make sure you have an anode fitted to your vessel so you reduce the risk of your propeller and stern gear from getting electrolysis. Don't forget to check that the anode you select is suitable for the type of water you normally keep your boat in, i.e. salt water = zinc or aluminum anodes or fresh water = magnesium anodes. Don’t forget that the anode needs to be in the water to work, if you lift your engine make sure either the whole thing is clear of the water or that the anode is in the water to give protection to the submerged parts.

(6) Keep the propeller clean, it is very surprising the amount of speed and efficiency that will be lost if the propeller has any growth on it. This principle will also apply to the lower unit and indeed the hull of the boat, the cleaner it is the faster it will go.

(7) When removing propellers do not apply any heat as this will damage the bush

Don’t forget if you keep your boat propped to perfection it will give you many hours of happy and efficient boating.

HAPPY BOATING !!